Semiconductor Metrology: Key Applications of Cold Cathode Technology in Vacuum Pressure Measurement

Semiconductor Metrology Series – 2

Cold cathode gauges, also known as Penning gauges, are used to measure vacuum pressure in a variety of applications, including semiconductor manufacturing. These gauges are necessary to maintain the vacuum conditions required in processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and etching in semiconductor metrology. Accurate vacuum pressure measurement is critical for ensuring the quality and consistency of semiconductor fabrication processes.

How Cold Cathode Gauges Are Used in Semiconductor Manufacturing Metrology

Cold cathode gauges play a crucial role in maintaining precision and reliability in semiconductor manufacturing.

- Process Monitoring: These gauges continuously track vacuum pressure in process chambers, ensuring stable conditions for critical operations like thin-film deposition and plasma etching. Consistency here is key to high-quality outcomes.

- Leak Detection: By identifying even minor pressure changes, cold cathode gauges help pinpoint leaks, ensuring chambers maintain optimal pressure for seamless performance.

- System Diagnostics: During maintenance and troubleshooting, these gauges verify vacuum system integrity, enabling quick resolutions and uninterrupted operations.

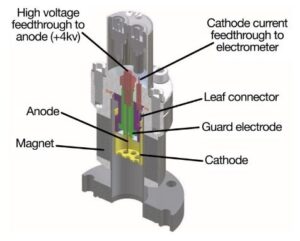

How Cold Cathode Gauges Work

Cold cathode gauges operate using a combination of electric and magnetic fields to measure vacuum pressure.

- Electrodes and Magnetic Field: A high voltage applied between the cathode and anode generates an electric field, while a magnetic field causes electrons to spiral. This movement increases the chances of gas molecules becoming ionized.

- Pressure Measurement: The ionized gas creates a current, which is directly proportional to the gas density. This current provides an accurate reading of the vacuum pressure.

Role of Magnetics within the Cold Cathode

Magnetics play a crucial role in the operation of cold cathode gauges. The magnetic field inside the device causes electrons to spiral, effectively extending their travel path. This longer path increases the chances of electrons colliding with and ionizing gas molecules, which is essential for accurately measuring vacuum pressure. This is needed to achieve accurate and reliable pressure measurements, especially in low-pressure environments.

Key Considerations in Magnetic Component Design for Cold Cathode Gauges

Designing magnetic components for cold cathode gauges requires precision and careful attention to detail.

- Magnetic Field Strength and Uniformity: A strong, uniform magnetic field ensures electrons spiral effectively to maximize ionization and maintain consistent pressure readings. Even small variations in the field can lead to measurement inaccuracies.

- Magnet Placement: Proper placement of magnets is essential to create the right magnetic field pattern. The field must be perpendicular to the electric field and cover the entire ionization region for optimal performance.

- Material Selection: Materials with high magnetic permeability and stability are crucial. Permanent magnets are often preferred as they provide a consistent magnetic field without requiring external power.

- Temperature Stability: Magnetic field strength can change with temperature. To address this, materials with low temperature coefficients or temperature compensation techniques are used to maintain accuracy.

- Size and Geometry: Magnetic components must be carefully designed to fit within the compact structure of the gauge while still delivering the necessary field strength and uniformity.

Each of these elements ensures the reliable and accurate performance of cold cathode gauges in demanding applications.

More in our Semiconductor Metrology Series

Learn More About High-Performance Magnetic Solutions

At Dexter Magnetic Technologies, we specialize in designing advanced magnetic solutions for precision applications, including cold cathode gauges used in semiconductor manufacturing. Contact us today to learn more about our expertise in magnetic component design and how we can help optimize your vacuum measurement systems!