Magnetic Beam Control: Principles, Applications, and Advancements

Many scientific and industrial applications require accurate and efficient focusing and deflection of ion and electron beams. Magnetic technology is essential for controlling these charged particle beams. In this article, we explore magnetic beam control, its applications in a wide range of industries, and emerging technologies.

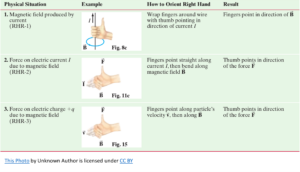

Essentially, magnetic beam control is based on Lorentz force, which describes the force exerted on a charged particle moving through a magnetic field: F = q(v × B)

As a result of this cross product, the particle follows a curve as it follows a force perpendicular to both velocity and magnetic field vectors. In the case of a particle moving at velocity v perpendicular to a uniform magnetic field B, the radius of curvature r is: r = mv / (qB)

A magnetic lens creates a radial force that pushes particles toward the beam axis. Its focal length f is approximated by the following formula, where B(z) is the magnetic field strength along the beam axis: 1/f = (q/2mv) ∫ B²(z) dz

Magnetic beams are used in many industries:

- Semiconductor Manufacturing

- Electron beam lithography

- Ion implantation

- Scanning electron microscopes (SEM)

- Medical and Life Sciences

- Electron microscopy for biological samples

- Particle therapy for cancer treatment

- Mass spectrometry for molecular analysis

- Materials Science and Engineering

- Transmission electron microscopes (TEM)

- Focused ion beam (FIB) systems

- Particle accelerators for materials analysis

Gyrotron – high-power linear-beam vacuum tubes that generates millimeter-wave electromagnetic waves

- Display Technology

- Cathode ray tubes (CRT)

- Electron beam welding

- Scientific Research

- Particle physics experiments

- Synchrotron light sources

- Free-electron lasers

Device Operation and Magnetic Components

Electron Microscopes:

These devices use electron beams to create high-resolution images of samples. Electromagnetic lenses focus the electron beam, while deflection coils steer it across the sample. Both electromagnets and permanent magnets are used in modern designs, with superconducting magnets employed in high-end systems for stronger fields and better resolution.

Particle Accelerators:

Large-scale accelerators use a combination of electromagnets for beam steering and focusing. Dipole magnets bend the beam, quadrupole magnets provide focusing, and higher-order magnets correct for aberrations. Superconducting magnets are often used to achieve the high field strengths required.

Ion Implantation Systems:

These devices use electromagnets to separate ions by mass and control the ion beam’s direction and focus. Hybrid magnets, combining electromagnets and permanent magnets, are sometimes used to reduce power consumption while maintaining flexibility.

Critical Aspects of Magnetic Component Design

- Field uniformity and stability

Electromagnet Assembly - Heat management and cooling systems

- Shielding to prevent interference

- Material selection for optimal magnetic properties

- Power supply design for precise current control

- Mechanical stability and vibration isolation

- Integration with vacuum systems

- Scalability for different beam energies and currents

Emerging Technologies

- Plasma-based focusing for compact particle accelerators

- Adaptive optics for real-time beam correction

- Machine learning algorithms for beam optimization

- High-temperature superconducting magnets for stronger fields

- Laser-plasma accelerators with magnetic beam transport

- Quantum sensors for ultra-precise magnetic field measurements

At Dexter Magnetic Technologies, we specialize in designing and manufacturing advanced magnetic systems for beam control applications. Our team of magnetic experts can support you throughout the development process, from initial concept to final production. Whether you need custom electromagnets, permanent magnet assemblies, or complete beam control solutions, we have the expertise and capabilities to meet your specific requirements.

Let’s work together and discuss your project and discover how our magnetic beam control systems can make a difference.